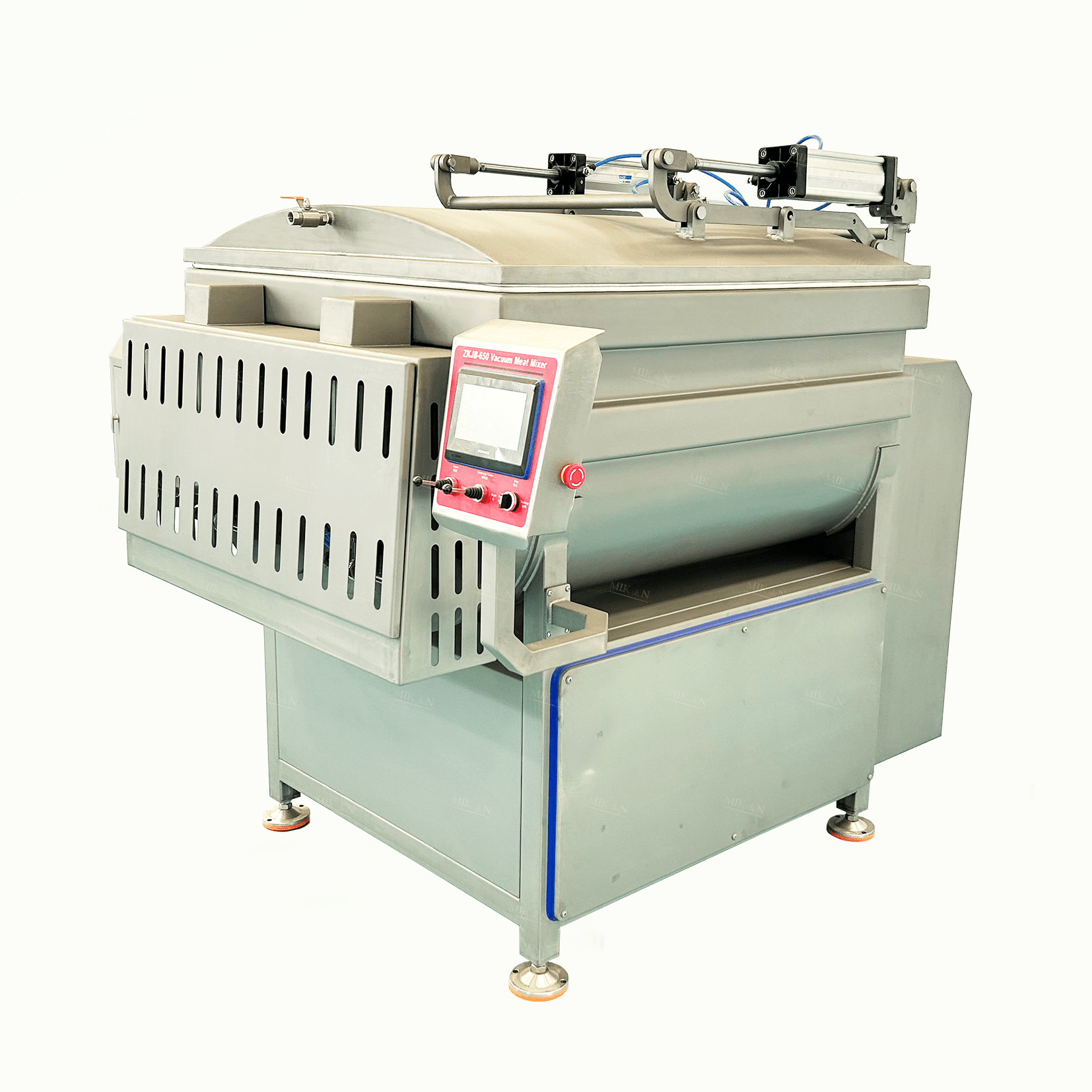

Vacuum Meat Mixer Machine 300-650L

Mixing meat with kinds of additives.

Additional information

| Model | ZKJB-300,ZKJB-650 |

|---|---|

| Volume | 300L, 650L |

| Capacity | 280kg/time, 500kg/time |

| Power | 5.15kW, 9.5kW |

| Mixing Speed | 26-38r/min |

| Vacuum Level | 0~(-0.085MPA) |

| Voltage | 380V (customized) |

| Dimension | 1425*1240*1470mm,1711*1400*1611mm |

Product Details:

1. The structure of this machine is reasonable, the appearance is beautiful and novel, and it is made of all 304 materials.

2. Pneumatic control is used to open and close the box cover and discharge cover, which is convenient and labor-saving.

3. Different types of paddles could be chosen. The mixing direction can be changed anytime to meet various process requirements.

4. The vacuum system is equipped with a material separator. When the separator is full, the suction port will automatically close to prevent the material from being sucked into the vacuum pump.

5. The newly designed and developed upper and lower shafts greatly shorten the mixing time and improve the mixing effect.(If need this design, please inform us in advance when placing an order)