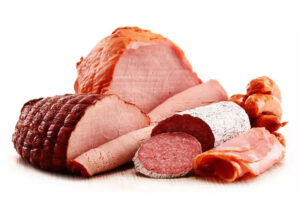

Application Trend of Natural Preservatives in Meat Products

Meat contains a large amount of protein and trace elements needed by human beings, but due to the hi

Meat contains a large amount of protein and trace elements needed by human beings, but due to the hi

1. Monomer Glue (+salt) The basic viscosity of the monomer colloids that can be gelled is not high,

Most meat products have to go through the process of marinating in the process of processing, which

1. Ingredients and Seasoning Chicken 16kg, pig fat 2kg, chicken skin 2kg, salt 0.35kg, white sugar 0

1. The unit of disinfection water concentration is PPM, which means one part per million or 1/100000

1. Hygienic Requirements for Casing Raw Materials Carcasses from healthy animals must be collected a

In surimi preparation engineering, product quality is affected by many factors. Carrying out the ada

Source of Odor The fishy smell and odor of pork is the product of excessive protein breakdown. Pork

1. Packaging Purpose Packaging is mainly to ensure the integrity of the product and avoid physical,

Vacuum tumbling is a physical process of energy conversion in meat pieces. It is an indispensable pr

There are many packaging products of low-temperature meat products in the market. There are hams, sa

Soybean is one of the main crops in China. Not only can it be used to extract edible oil, but its ri

The mail will be sent to Ms. Mandy. You will get a response in 1-2 hours!