Automatic Multi Forming Machine AMF600IV and AMF400II

Updating the system comprehensively :

- It can be suitable for metal forming plates

- The protective grade for the electric apparatus parts reach toIP67

- The speed increases to 70 stokes/min

- Weight error margin≤5%

- New user interface

- To avoid the operation mistake, with high safe

Additional information

| Model | AMF600-IV, AMF400-II |

|---|---|

| Width of the Belt | 600mm, 400mm |

| Air/ Water Pressure | 6Bar/2Bar, 6Bar/2Bar |

| Power | 15.12kW, 11.12kW |

| Capacity | About 500-1000kg/hour, About 200-600kg/hour |

| Stroke | 30~70 Strokes/minute, 15~55 Strokes/minute |

| The Thickness of Product | 6~40mm, 6~25mm |

| Weight Error | ≤1%,≤1% |

| The Maximun Diameter | 150mm(for round burger), 135mm(for round burger) |

| Filling Presssure | 3~15Mpa Adjustable, 3~15Mpa Adjustable |

| Dimension | 3170*1176*2430mm, 2828*830*2136mm |

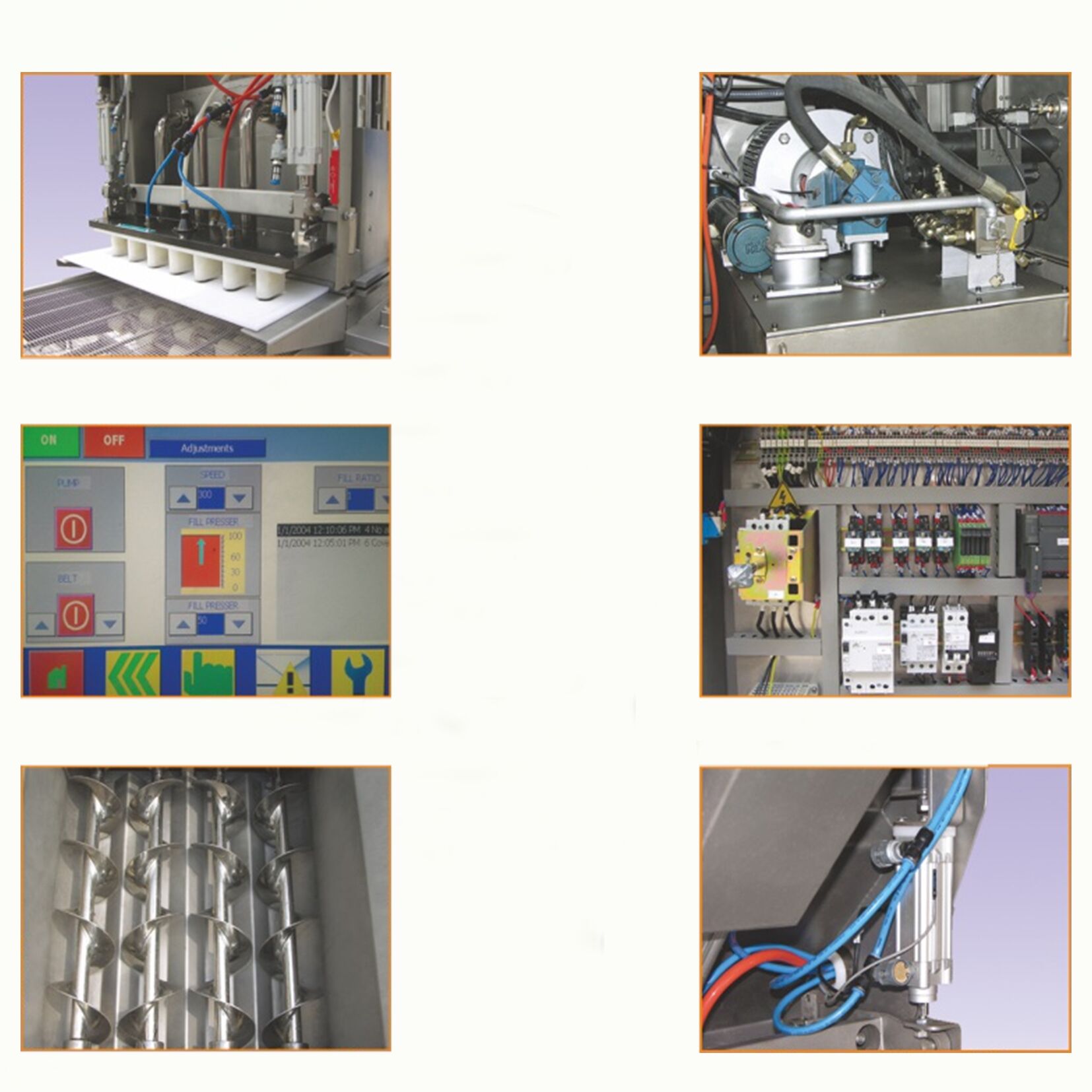

Product Details:

AMF600-Ⅳ, AMF400-Ⅱ Automatic Multi Forming machine can automatically perform various procedures such as meat filling, forming and outputting, and combine a fully automatic prepared food line when connecting with the batter, preduster, fryer, cooker, instant freezer, and packing machine. It adopts the method of a four-screw feeding system, greatly reduces the cutting of the material, and has better features of high production capacity and stable quality.

Easy and convenient replacement of food and accurate portion control realize the cost control of the production.

Widely handles in the forming procedure of meat, poultry, fish, shrimp, and the potato, tuber crops. And it can be applied in the fields of all kinds of minced/sliced products for premier meat texture taste.

Electric apparatus parts: Using original Germany SIEMENS PLC processor with touch screen operation, Chinese/English operating

system and automatic failure alarm system.

Safe device: Magnetic protection switch (safe cover).

Hydraulic parts: Adopting the VICKERS, STAUFF, PARKER, INTERGRADTE HYDRAULIC original parts to guarantee the stable running of the whole machine.

Pneumatic system: Adopting the completely German FESTO original system.

Stainless steel made and portion non-metal material, safe and reliable, in conformity with the standard of HACCP, and got the CE authorization.