Sausage Peeling Machine

It can easily and quickly cut open twisted cellulose casing sausages, and peel and remove the casing. Effectively saving manpower, improving work efficiency, reducing enterprise costs.

Additional information

| Speed | 30-190m/min |

|---|---|

| Power | 4.1kW |

| Air Pressure | 0.4-0.5MPa |

| Steam Pressure | 0.02MPa |

| Weight | 306kg |

| Dimension | 2300*820*1450mm |

Product Details:

1. It can easily and quickly cut open twisted cellulose casing sausages, and peel and remove the casing. Effectively saving manpower, improving work efficiency, reducing enterprise costs.

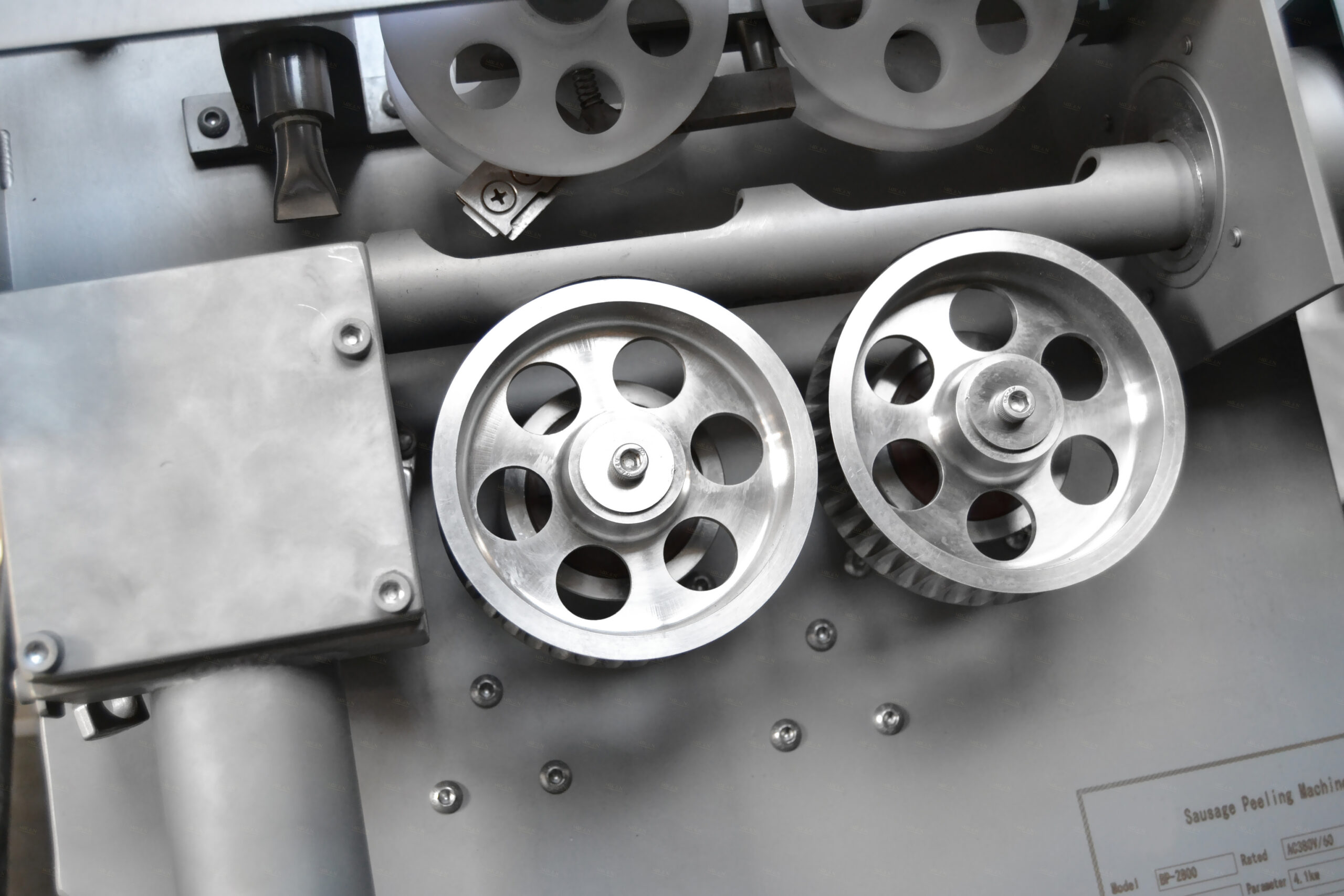

2. Working principle: The motor drives the driving wheel to rotate, so that the sausage passes through the steam pipe. Under the dual action of the driving wheel and the upper roller, it is sent to the blade to cut the casing. The air pipe at the top is connected to the air source to blow the casing open and separate it from the sausage. Under the action of the fan, the casing is sucked into the box where the casing is stored.

(1) Pipe (2) Steam Pipe Jacket (3) Ball valve (4) Pipe (5) Driving Wheel (6) Adjusting Bolt

(7) Upper Roller (8) Blade Component (9) Air Pipe (10) Sealing Guide Sleeve

3. The accessories are all processed by CNC machining to ensure precise movement, only cutting through the casing without damaging the intestinal body.