Quick-frozen meatballs generally refer to spherical foods made with chopped meat as the main ingredient. They are usually quick-frozen formed by steaming or deep-frying mixed flavored meat materials. The product varieties mainly include fish balls, pure meatballs, mushroom balls, beef balls, beef tendon balls, sandwich meatballs, fried beef balls, etc., which are stored and transported in the cold chain.

1. ProcessingFlow:

Raw and Auxiliary Material Pretreatment → Beating → Forming → Low-Temperature Pre-cooking → High-Temperature Cooking → Water Cooling → Air Cooling → Selection → Quick Freezing → Bagging, Weighing, Sealing → Metal Detection → Coding → Packing, and Storage → Refrigeration

2. Operation Points:

2.1. Raw Materials Pretreatment

Defrosting: beef, pig 4# meat, pig 2# meat, and chicken breast meat are pulled out of the cold storage in advance, and they are thawed naturally or thawed and air thawed. The specific thawing time depends on the surface thawing thickness ≥0.5cm, and the core temperature before minced meat is -10~-2℃.

Unpacking: first, remove the outer carton, layer the dismantled outer carton on the backing plate, then sprinkle the inner packaging film, and look back and forth to see if there is any plastic film in the raw meat. If there is any, use a knife to remove it in time. The whole process must be operated on a special stainless steel workbench.

Cut and mincemeat: Put the unpacked raw meat into the dicing machine, and then put it into the meat grinder and use a 6mm grinder to squeeze out. The meat ingredients are twisted according to the number of recipes in each pot. Do not twist more or less, except if it is the smallest package that requires more twists, weigh the more twisted quantity and wait for it to be used in the pan. The reaming net and the reaming knife should be removed every day after get off work to check whether they are worn out. If worn, they should be polished by maintenance personnel or replaced with new ones.

2.2. Processing of Drawing Type Soy Protein

Picking and soaking in water (cold water must be used, hot water is not allowed, the ratio of water should be more than 7 times of the dry matter): Put the dried silk protein into the bucket, then add water, and after the water is full, let it cover with water. The soaking time is controlled at 1 ~ 2.5h. In the middle, use your hands to press the upper egg white into the water, and let it roll to achieve uniform water covering effect. The degree of soaking should be such that there is no hardcore in the middle of each piece, and the moisture absorption is sufficient.

Dehydration: Put the soaked silk protein into a mesh bag, 1/2 each bag, and put it in the dehydrator. Put 4 ~ 6 bags each time and turn on the dehydration device.

Judgment of the qualified effect of dehydration: one is to look at the dripping situation of the water outlet of the dehydrator, starting from the big to the very small water flowing out at the end; the second is to grab a hand, and then squeeze it forcefully, as if there is no or a small amount of water is squeezed out. The whole dehydration time is 1~2min.

Chopping. Pour the brushed protein into a small chopping machine in a quantity of no more than 2 bags. The degree of shredding is needle-like. The time is 0.5~1.5min. It is not allowed to be chopped into powder and granular.

The material preparation matches the production schedule, and you can prepare as much as you need. The storage time of the prepared materials at room temperature shall not exceed 2h, otherwise, it shall be stored in the fresh-keeping warehouse and the storage time shall not exceed 4h.

2.3. Beating

The meat used for stuffing should not be too thawed except for the pig 2# minced meat. After adding the materials in each process, the speed should be slow and then fast prevent the slurry from being thrown out of the beating barrel. During the pulping process, the feeding sequence and the final product temperature are the key control points.

2.4. Molding, Cooking

The shape of the product is formed by different machines and falls into the water tank for high-temperature gel curing. Generally divided into two stages of boiling: small boiling line, the temperature of the first stage is controlled at 70~80℃, the temperature of the second stage is controlled at 92~98℃; for the large boiling line, the temperature of the first stage is controlled at 70 ~75℃ (about 12~30min), the temperature of the second stage is controlled at 88~95℃ (about 5~10min). Product center temperature after boiling: solid type ≥75℃, sandwich-type ≥68℃.

2.5. Feeding

Feeding personnel pay attention to the uniformity of sizing, do not feed too much at a time, nor should it be too little, to prevent the product specification deviation from being too large. In addition, do not use too much force, and try to prevent too much gas from being transferred, resulting in uneven pressure and different product specifications.

Due to the poor stability of the machine, the sampling is judged based on 5 consecutive samples. The feeder pays attention to the sanitation of the machine and cleans the material around the hopper at any time to prevent it from falling into the sink and becoming a defective product.

2.6. Picking

The material receiver selects the cooled products according to the requirements, and selects the deformed products, cracks, etc. The sandwich-type allows slight leakage of juice (the size of the breach is within 2mm) below 3%, and it is placed in the specified position. Keep it at room temperature for no more than 3 hours in summer and no more than 4 hours in winter to prevent acid deterioration.

2.7. Water Cooling

The steamed balls are directly transported to the cold water tank by the conveyor for cooling, reducing the temperature of the product.

2.8. Wind Cooling

The water-cooled balls are conveyed by the conveyor, and the temperature of the balls is further cooled by the air duct set on the production line, so that the center temperature of the product is close to normal temperature for quick freezing.

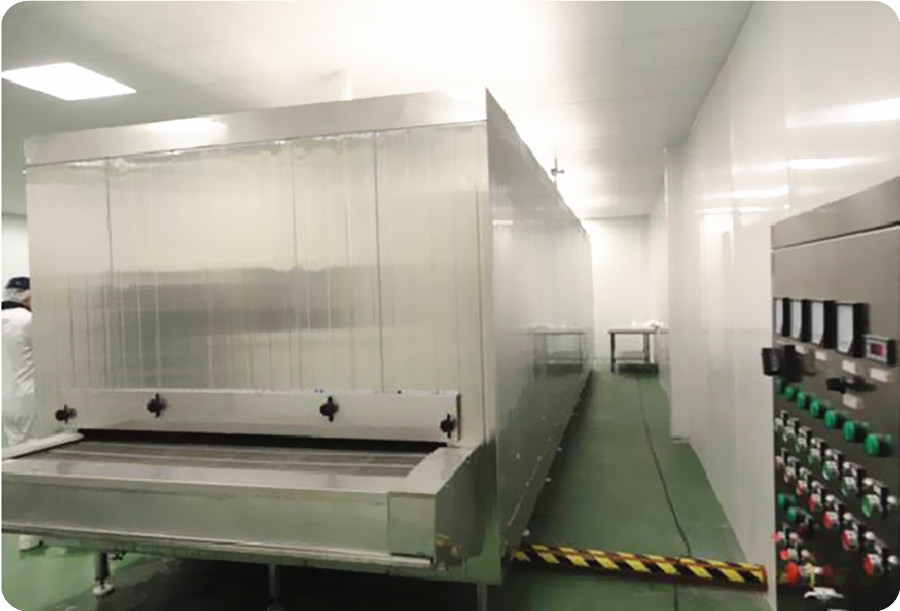

2.9. Quick Freezing

When the temperature of the tunnel reaches below -25℃, the balls can be fed, and the center temperature of the product at the exit of the quick-freezing line is below -10℃. During the freezing process, the speed of the single freezer is adjusted according to the characteristics of each product to ensure the freezing effect.

2.10. Bagging, Weighing, Sealing

Before using the inner packaging, ensure that the label is correct, the name of the product on the packaging bag and box is clear, and the packaging bag is free from foreign matter and pollution. The packaged product requires a flat and beautiful seal (air leakage is allowed in the case of a tight seal), to ensure that the product’s inner packaging date and packaging specifications are consistent with the outer box. The date is required to be printed clearly and accurately, no missing, reprinted, or incomplete, and the year, month and day are accurate. The packaging specification is 1x250gx4 bags or 1x500gx20 bags.

2.11. Packing

Folding is allowed in the bag, as long as the pack appearance does not affect the senses.

2.12. Back Sealing

There is no requirement for the back seal to reveal white and embossing characters, as long as the product is packaged tightly.

2.13. Packaging Exhaust

Pack exhaust as far as possible, so as not to cause rotten bags.

2.14. Metal Detection

After sealing or before entering the packaging machine, each bag of products must be inspected by a metal detector. The test piece must be used for 3 consecutive tests when the equipment is turned on or when the specifications are changed. During the production process, the test piece must be used for 3 consecutive tests every 30 minutes. Each bag of products must pass a metal detector. If any metal is detected, quickly process and open the bag to analyze the source, timely feedback-related procedures, and strengthen control. If the test piece is not detected, the machine should be stopped for adjustment immediately, and the normal product tested last time should be isolated and re-tested.

2.15. Coding, Packing and Storage for Refrigeration

Packing requires the product name, specification, and production date to be consistent inside and outside, the packing box is sealed smoothly, the tape on both sides is not longer than 5cm, and the name and date of the box body must be clear when coding. Each backing board should be placed no more than 7 layers, the product staying time before storage should not exceed 30min, and the finished product should be stored in a cold storage ≤-18℃.

3. Problems and Solutions that are Prone to Occur in the Production Process

3.1. Beating Process

Due to the viscosity of the slurry, the operation of the mixer during the pulping process will generate a lot of heat that cannot be dissipated. The temperature of the slurry should be controlled at 5~10℃. At the same time, crushed ice should be added to reduce the viscosity of the slurry. According to the actual situation control, the amount of ice added and the use of block ice, not excessive or insufficient.

3.2. Forming Process

The feeding personnel pay attention to the sanitation of the machine, and clean the slurry around the hopper at any time to avoid falling into the sink and becoming defective; pay attention to the uniformity of the feeding, not too much at a time, not too little, to prevent the product specification deviation from being too large. The material bucket should be placed as far away as possible from the boiling tank, pay attention to the change of the slurry.

3.3. Biological, Chemical and Physical Hazards

There may be biological, chemical, and physical hazards in the production of quick-frozen meatballs. The pathogenic bacteria in the finished products exceed the standard, especially Staphylococcus aureus, and the pesticide residues in various raw and auxiliary materials will cause the finished meatballs to exceed the standard. The use of tools and instruments, due to untimely replacement or improper protection, mixed metal foreign objects in the finished meatballs.

3.4.Strictly Operate in Accordance with GMP\SSOP\HACCP Specifications

During the processing of quick-frozen meatballs, the entire process from raw material inspection to finished product formation may be contaminated to varying degrees. During processing, the process parameters of each process should be mastered, production and processing should be carried out in strict accordance with GMP\ SSOP\HACCP and other operating specifications, and the quality and hygiene indicators should be monitored throughout the process.