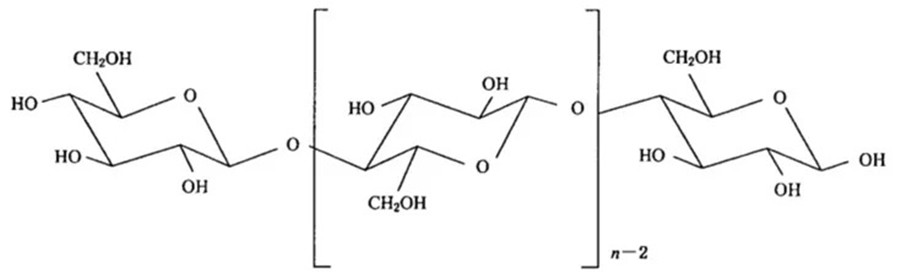

Cellulose is the most widely distributed and abundant carbohydrate in nature. Plants around the world can produce more than tens of billions of tons of cellulose every year, making this polysaccharide the largest organic carbon pool.

Among various sustainable resources, cellulose has an inexhaustible material basis. As the only carbon-renewable resource, it is generally believed that it can supplement or partially replace non-renewable resources and become an important resource on which the future development of mankind depends.

1. Fiber Profile

Cellulose is composed of alternating crystalline and amorphous regions. Most of the hydroxyl groups in the amorphous region are in a free state on the glucose ring and are prone to chemical reactions. However, the large hydroxyl groups in the crystalline region form a large number of intramolecular and intermolecular hydrogen bonds, which seriously hinder the effective contact and interaction of the cellulose surface with chemical reagents or biological enzymes. This is extremely disadvantageous to its molding, processing, and application.

Therefore, the use of physical, chemical, or biological methods to change the inherent properties of cellulose, form cellulose derivatives with other functional properties, and to develop the application of modified cellulose in various fields, has become a current research focus.

Different modified celluloses have different effects on meat products. Such as microcrystalline cellulose, carboxymethyl cellulose, hydroxypropyl methylcellulose, and other etherified celluloses, as well as bacterial cellulose (BC) and nanocellulose prepared by special processes. Appropriate addition as an ingredient in meat products can improve the quality of meat products to varying degrees. It has effects on improving gel properties, reducing cooking loss, reducing fat content, and extending shelf life.

Therefore, it is extremely necessary to understand the characteristics of modified cellulose and its interaction mechanism with meat proteins, and to select appropriate types and dosages for different products.

2. Modified Cellulose

Modification is to introduce functional groups or other elements through the hydroxyl groups on the surface of cellulose, change part of its chemical structure and properties, and finally become a macromolecular substance with special functions. There are three main methods: chemical modification, physical modification, and biological modification, among which chemical modification is widely used and studied.

3. Application of Modified Cellulose in Meat Products

Meat is a great source of high-quality protein and many micronutrients with high biological value. Modified cellulose can be used as a thickener, stabilizer, water-retaining agent, emulsifier, etc. in meat processing. It can interact with the proteins and lipids in it to form emulsified droplets, which are bound in the three-dimensional network structure of proteins in the form of copolymers or fillers. Thereby, the voids of the emulsified meat gel are reduced, and the thermal stability of the protein and the gel strength of the system is improved.

At the same time, it can adjust the rheology and network structure of the continuous phase in the dispersion system, delay phase separation, and emulsion stratification caused by gravity. It can also adsorb on the oil-water interface, forming a steric barrier around the emulsified droplets, reducing interfacial tension and preventing droplet coalescence.

3.1. Mechanism of Interaction with Meat Proteins

Meat proteins include myofibrillar proteins, sarcoplasmic proteins, and connective tissue proteins mainly composed of collagen. During meat processing, myofibrillar proteins aggregate around oil droplets and participate in the formation of three-dimensional network gels that help improve emulsion stability, water-holding capacity, and meat product texture.

The more hydrogen bonds between fiber and meat protein, the stronger the product. After the modification of cellulose, some active groups are introduced, the crystallinity and aggregation degree are reduced, the accessibility is improved, and the interaction between cellulose and meat proteins is changed, resulting in sensory changes in meat products.

Meat protein forms a network structure after heat denaturation, and the added modified cellulose can absorb and bind the moisture lost by protein during heat denaturation in time with its special structure, thereby improving the sensory properties of meat products.

3.2. Effects on Gel Properties, Emulsifying Properties, and Water Retention of Meat Products

During the processing of recombinant meat products, the intramolecular and intermolecular bonding or interaction of proteins determines the rheological properties of meat emulsion and the physical properties of heat-induced gels. Modified cellulose can provide cohesion in recombinant protein gels. , and its effects on the gel properties, emulsification properties, and water retention of meat products are shown in Table 1.

| Fiber Type | Product | Research Result |

| CNF | Emulsified Sausage | Reduced fat content and cooking losses in sausages, high moisture content, and lightness values |

| HPMC | Surimi | It can stabilize the surimi gel structure and improve its rheological properties. |

| RC | Minced Meat | Reduced oil droplet size and improved emulsion stability |

| CMC | Low-fat Frankfurters | Low molecular weight CMC leads to decreased emulsion stability |

| BC | Dolphin Surimi | Has the properties of a cellulose-protein phase-separated network hybrid gel to improve the gel strength of dolphin surimi |

| BC | Chinese Meatballs | For better juiciness and chewiness |

| BC | Chicken Pie | The microstructure is more compact, and the chewiness decreases when the addition of BC is 0.6% |

| BC | Emulsified Sausage | Reduces cooking loss of emulsified sausages, improves its texture properties and fat distribution, and makes the structure uniform |

3.3. Application of Modified Cellulose in Low-fat Meat Products

Fat content is closely related to the taste and flavor of meat products. It mainly plays the role of emulsification, reducing cooking loss, improving water holding capacity, and improving product flavor, juiciness and tenderness. With the improvement of people’s consumption level, excessive fat intake will lead to potential hazards such as obesity, hypertension, and hyperlipidemia. Reducing the fat content in meat products and choosing suitable substitutes have attracted the attention of many scholars.

CMC and MCC are potential fat substitutes for meat products. When the CMC concentration exceeded 0.5%, the microstructure, sensory and textural properties of the beef patties were different. When MCC was added at a concentration of 2%, the fried beef patties were soft and juicy, with the best sensory score and a fat-like mouthfeel.

This is because when the concentration of CMC is high, the strength of the protein network structure formed after heat treatment decreases, while MCC is highly compatible with beef protein matrix, and after heating and frying, a protein network containing meat particles and fat particles can be formed, which makes the product texture. Improved. CMC can reduce the texture hardness of high-protein, low-fat sausage recipes. MCC can improve the integrity of the protein gel network. This combination can be used to produce healthy meat products with lower fat content.

The combination of HPMC and rapeseed oil was constructed into a solid oil gel to replace animal fat (tallow) to reduce saturated fat levels in meat patties. The hardness and shear force of HPMC was significantly higher than that of tallow, the cooking loss of the patty was significantly reduced at the 50% replacement level, and the texture became softer, with the highest overall acceptability. Significantly reduces the ratio of saturated fat to unsaturated fat, resulting in a more nutritious patty.

Amorphous cellulose is also a low-calorie, non-digestible, tasteless fiber, usually obtained from grain sources. Has good water retention capacity, increases viscosity, and provides the same organoleptic properties as fats such as juiciness and texture. The incorporation of amorphous cellulose reduces fat and cholesterol levels in emulsified cooked sausages. Replacing pork fat with 50% can reduce the fat and cholesterol content of fermented sausage by 45% and 15%, respectively.

3.4. Application of Modified Cellulose in Meat Product Packaging

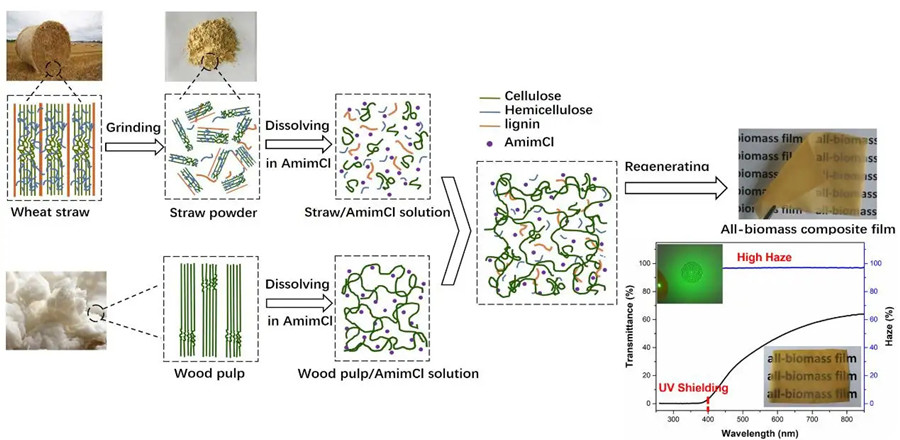

After modification, natural cellulose has good film-forming properties, excellent mechanical strength, and chemical stability, and can be used as a packaging film in the food industry.

Meat and its derivatives are highly perishable foods that can spoil rapidly under inappropriate storage conditions. Edible films or coatings provide an efficient way to preserve and package these foods. The shelf life of meat products can be improved by preventing moisture loss and inhibiting microbial growth. In particular, nanocellulose membranes have the characteristics of high mechanical strength, small particle size, and complete degradability. The cellulose-rich agricultural and sideline products represented by the fruit peel, shell, core, seed, straw, bagasse, etc. have been used as a preparation source by many researchers.