Smoked sausage is one of the main types of meat products on the market. It is usually made from poultry and livestock meat through the processes of twisting, mixing, marinating, filling, sterilizing, cooling, and packaging.

In order to meet the diverse needs of the consumer market, cheese, corn, coconut, and smoked sausage are combined. After the optimization of the formula, it satisfies people’s pursuit of the new flavor, nutrition, and health.

1. Basic Formula

Pork 25kg, chicken breast 20kg, chicken skin 8kg, water 15kg, white sugar 5kg, salt 0.5kg, phosphate 0.3kg, sodium nitrite 0.005kg, flavor 0.5kg, soybean protein isolate 1kg, starch 3kg, monascus red 0.012kg.

2. ProcessingFlow

Raw Meat→Cutting→Grinding→First Mixing (adding pickling water, emulsion)→Marinating→Second Mixing (adding corn, cheese, coconut granules)→Filling→Sterilization→Cleaning→Drying→Packing.

3. Operation Points

3.1. Cutting

The raw materials that meet the requirements are repaired to remove residual lymph, cartilage, broken bones, air-dried oxide layer, impurities, etc.

3.2. Grinding

The raw material is minced with an 8mm hole cutter, and the emulsion material is minced with an 18mm hole plate.

3.3. Pickling Material Preparation

The salt, white sugar, phosphate, sodium D-isoascorbate, sodium nitrite, pigment, flavor and other auxiliary materials other than starch in the formula are mixed with ice water to form the raw water.

3.4. The First Mixing

Add marinades and emulsions, stir in vacuum for 30 minutes, and the vacuum degree is required to be ≥0.085MPa.

3.5. Pickling

After mixing, place the meat material at 0~6℃ and let it stand for 15~20h.

3.6. The Second Mixing

Adding the corn, cheese, and coconut granules to the pickled material, and mixing for 20 minutes in a vacuum. The vacuum degree is required to be ≥0.085MPa.

3.7. Filling

Use PVDC casing to fill.

3.8. Sterilization

Before sterilization, check the pressure, seal, steam, and circulation pump of the sterilization pot. The process parameters are as follows: heating time 10min, constant temperature time 24min, sterilization pressure 0.20~0.25MPa.

4. The Influence of Various Factors

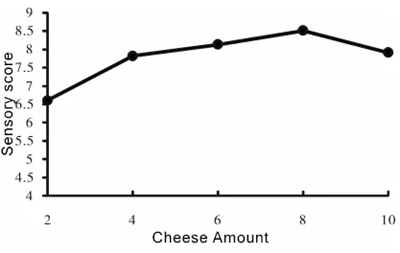

4.1. Added Amount of Cheese Granules

It can be seen from Figure 1 that when the amount of cheese granules is 8%, the sensory evaluation score of the product is the highest. At this time, the product tastes tender, elastic, and has the best chewiness. The cheese granules are obvious and the flavor is pure.

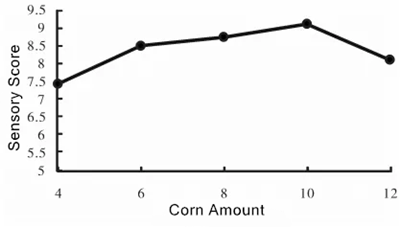

4.2. Added Amount of Corn

Figure 2 shows that when the amount of corn grains is 10%, the sensory evaluation score of the product is the highest, the chewiness of the product is relatively best, the flavor is coordinated, and the corn grains are obvious. When it is less than 10%, the change of corn grains will have little effect on the sensory evaluation of the product. The increase of corn grains will slightly worsen the product structure, but the graininess and chewiness will be improved; when the amount of corn grains added is >10 %, the structure of the product will become loose and the chewiness will become worse.

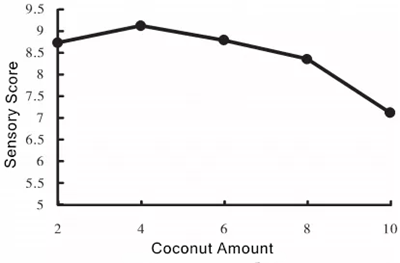

4.3. Added Amount of Coconut Granules

Figure 4 shows that when the sterilization temperature is 105°C, the sensory evaluation score of the product is the highest, the product has the best chewiness, harmonious flavor, and rosy color.

When the sterilization temperature is less than 105°C, the structure is harder and the chewiness is poor, and the flavor is strong; when the sterilization temperature is >105°C, the structure of the product becomes loose, the chewiness becomes worse, and the product color and odor appear at the same time.

5. Experimental Optimization Results

The addition amount of cheese is 8%, the addition amount of corn is 10%, and the addition amount of coconut is 6%, and it is steamed and sterilized at 102°C for 24 minutes. Under the conditions of this ratio and sterilization process, the color, taste and flavor of the product are excellent.