Beef is the world’s third most consumable meat product. It is rich in protein, amino acids, and B vitamins, and has the characteristics of low fat and low cholesterol. With the improvement of people’s living standards, beef has become an ideal choice for consumers who pursue nutrition and health. At present, beef products sold on the market generally have shortcomings such as hard meat and poor tenderness, which seriously affect the quality of meat products. In order to improve these shortcomings, beef needs to undergo tenderization in the production and processing process.

Alkaline tenderization is a traditional tenderization process. Since ancient times, China has been adding soda ash to stewed beef to improve beef tenderness. Many studies have confirmed that alkaline substances are used in meat marinating to have a good tenderization effect. For example, the marinating preparation made of phosphate and Na2CO3 with a mass ratio of 1:8 has a very good tenderization for recombinant steaks. The combined effect of Na2CO3 and inulin can effectively improve the tenderness and water retention of recombinant chicken steaks. However, these studies usually use smearing or soaking for tenderization. This article discusses the tenderization effect of Na2CO3 injection on Simmental hybrid beef. Screen the appropriate concentration of Na2CO3 treatment, and explore the partial effects of Na2CO3 injection on beef muscle fibers and connective tissue.

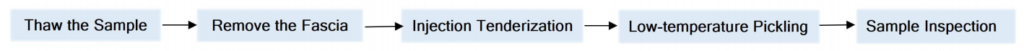

1. ProcessingFlow:

2. Sample Processing:

The frozen raw meat is thawed in a 0~4℃ environment for 24 hours to completely thawed. Then remove the fascia fat, and cut the meat sample into small pieces of 2cm×5cm×5cm along the direction of the muscle fiber, and weigh the sample.

A 1ml injector was used to inject Na2CO3 uniformly into different meat samples along the direction of the muscle fibers, with a fixed injection volume of 8% (percentage of sample mass), marinating time for 12 hours, and adjusting the Na2CO3 concentration to 0, 0.25, 0.3, 0.35, 0.4 mol/L.

The treated sample was sealed with cling film and placed at 0~4℃ for 12 hours, and then the surface water was drained with absorbent paper for detection test.

3. The Impact on Beef Quality:

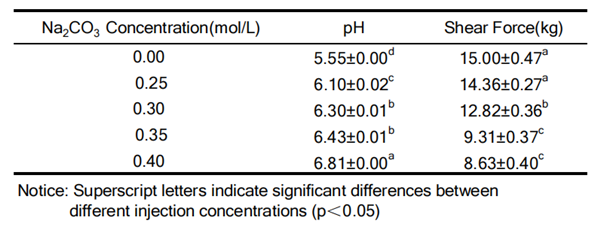

3.1. Effect on Beef pH

The pH value is an important quality indicator of beef, which is significantly related to water retention, tenderness, color, and other indicators. Table 1 shows the results of beef pH value changing with Na2CO3 concentration. The pH value of beef tenderized by Na2CO3 injection was significantly higher than that of the uninjected blank sample (P<0.05), and with the increase of Na2CO3 concentration, the pH value of beef gradually increased. This is because Na2CO3 is a kind of weak alkaline Sodium salt, its aqueous solution can significantly increase the pH value of beef. When the concentration of Na2CO3 increases to 0.4mol/L, the pH value of beef reaches 6.81 near neutral.

3.2. Effect of on Beef Tenderness

Tenderness is an important quality index of beef and one of the most important indexes affecting consumers’ choices. It is generally expressed by the shear force value. It can be seen from the data in Table 1 that the addition of Na2CO3 can significantly reduce the shear force of beef (P < 0.05) and improve the tenderness of beef. With the increase of Na2CO3 concentration, the shear force shows a significant downward trend. The improvement of beef tenderness by Na2CO3 is related to the improvement of beef pH value and muscle water retention. Some studies have also shown that the improvement of beef tenderness by Na2CO3 may be related to the change of pH value and the weakening of connective tissue.

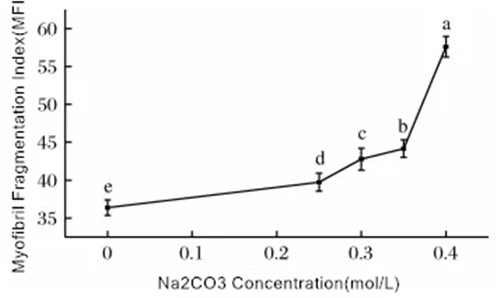

3.3. Effect on the Fragmentation Index of Beef Myofibril

Myofibril Fragmentation Index (MFI) represents the degree of myofibril decomposition and is an indicator of muscle tenderness. The larger the MFI, the greater the degree of damage to the internal structure of myofibrils and the better the tenderness of the meat. The results in Figure 1 show that the degree of myofibril breakage in beef increases with the increase of NaCO3 concentration. Especially when the Na2CO3 concentration reaches 0.35mol/L, the myofibril fragmentation index increases sharply, which is one of the main mechanisms of Na2CO3 tenderization. one.

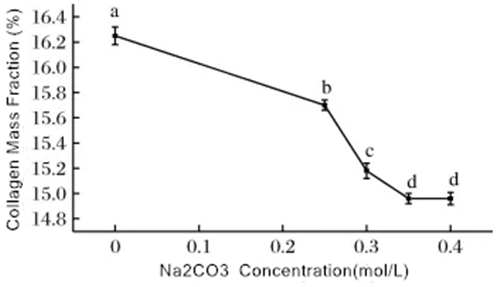

3.4. Effect on Beef Collagen Content

Connective tissue is a secondary component of muscle, mainly composed of collagen fibers, and its main component is collagen. Studies have shown that the tenderness of muscle is significantly related to the collagen content in perimysium and endomysium. From the data in Figure 2, it can be seen that Na2CO3 injection can significantly reduce the collagen content in beef. When the Na2CO3 concentration reaches 0.35mol/L, although the collagen content in beef decreases slightly, the difference is not significant.

Combined with the observation of the microstructure, it can be inferred that the decrease in beef collagen content is also related to the dissolution of beef myosin. The tenderness of muscle is inversely proportional to the collagen content and directly proportional to the soluble collagen content so that Na2CO3 can be effective. Improve beef tenderness, and the mechanism of improving beef tenderness is related to reducing collagen content and weakening connective tissue.

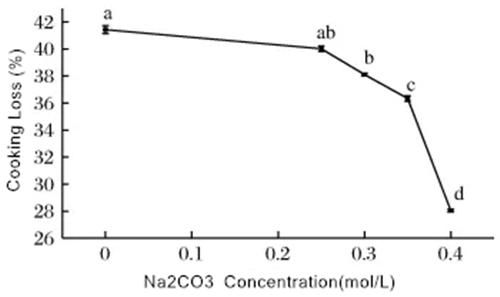

3.5. Effect on Beef Water Retention

Cooking loss is an important indicator of the water retention of meat, and it can reflect the ability of muscles to retain water. The effect of different concentrations of Na2CO3 on beef cooking loss is shown in Figure 3. With the increase of Na2CO3 concentration, beef cooking loss decreases significantly, and water retention is enhanced. Muscle water retention is closely related to pH. The isoelectric point of myofibril protein is about 5.2~5.4. The pH of the blank beef sample without the injection of Na2CO3 solution is 5.5, which is slightly higher than the protein isoelectric point. With the increase of the concentration of Na2CO3 injection, the pH value of beef gradually deviates from the isoelectric point improve. As the pH value of muscle increases and gradually deviates from the isoelectric point of myofibril protein (5.0~5.2), the negative charge on the surface of the protein increases, forming more hydrogen bond sites that bind to water molecules, and myofibril protein absorb water and swells. At the same time, as the negative charge increases, the electrostatic repulsion between protein molecules increases, causing mutual repulsion of myofilaments, myofibrils swell and thicken, the gaps between muscle fibers increase, and more water is retained.

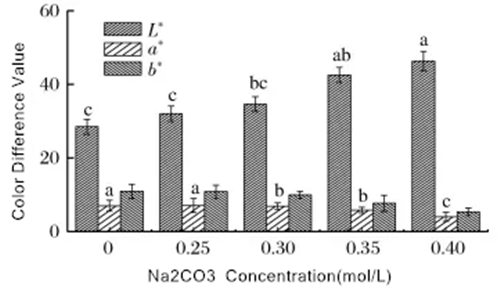

3.6. Effect on Beef Color

Color is the most intuitive indicator that affects consumers’ choice of meat products and is affected by many factors (such as water retention, pH, etc.). It can be seen from Figure 4 that as the concentration of Na2CO3 increases, the brightness value (L*) of beef gradually increases. When the concentration of Na2CO3 is 0.4mol/L, the L* value is the highest, and when the concentration is 0.35mol/L, L* The value is second and there is no significant difference between the two; the redness value (a*) of beef decreases with the increase of the concentration of Na2CO3, which shows that the high concentration of Na2CO3 will affect the color of the meat to a certain extent, and the yellowness value (b*) As the Na2CO3 concentration increases, it decreases, but there is no significant difference between the b* values of each sample. Therefore, it is not recommended to use high concentrations of Na2CO3 to treat beef.

3.7. Sensory Evaluation

Sensory analysis is the most intuitive indicator of product quality, which can clearly indicate the consumer’s acceptance of the product. As the injection concentration of NaCO3 increases, consumers’ acceptance of the color of the product continues to decline, which shows that NaCO3 will affect the color of beef to a certain extent; consumers’ evaluation of beef aroma does not show a significant rule This shows that NaCO3 has almost no effect on beef aroma; taste, tenderness, and juiciness are important indicators that affect beef quality. These three indicators all increase significantly as the concentration of NaCO3 increases. When the concentration of NaCO3 reaches 0.35 After mol/L, the taste, tenderness, and juiciness scores improved slightly, but there was no significant change from 0.35 mol/L. After adding NaCO3, consumers’ overall acceptability of beef increased significantly.