Smoked ham is refined by injection, tenderization, tumbling, and smoking of high-quality pork hind legs. The product is packaged in cellulose casing, which has an attractive smoky appearance and good color rendering on the cut surface. The meat has a full and pure aroma, and has a strong fruity wood smoky flavor.

1. Process Flow

Raw Material Selection → Pickling (saltwater injection) → Rolling → Filling → Steaming → Smoking → Cooling → Finished Product

2. Choice of Recipe

Lean meat 50kg, salt 1.1kg, phosphate 0.15kg, monosodium glutamate 0.1kg, mixed emulsifier 1kg, pepper 30g, nutmeg powder 15g, sodium erythorbate 25g, cinnamon powder 10g, sodium nitrite 5g.

3. Operation Points

3.1. Raw Material Selection

Choosing the right raw meat is a decisive factor in the production of high-quality ham. Generally, the hind legs of pigs are used, and the color should be bright, and the fat, tendons, tender bones, and soft tissues should be removed as much as possible. The raw meat should be fully cooled, with a pH value of 5.8-6.2, and a core temperature of 3-4°C.

3.2. Pickling

Dissolve all the auxiliary materials with clean water and filter them. Use a brine injection machine to inject the auxiliary material solution into the meat, and then send it to the cold storage at about 4°C for marinating for 12-16 hours.

3.3. Tumbling

The marinated meat needs to be tenderized and rolled for 2-3 hours, and the temperature for rolling should be below 8°C.

3.4. Filling

Use a vacuum sausage stuffer to pour the meat into the cellulose casing and ligate and seal it.

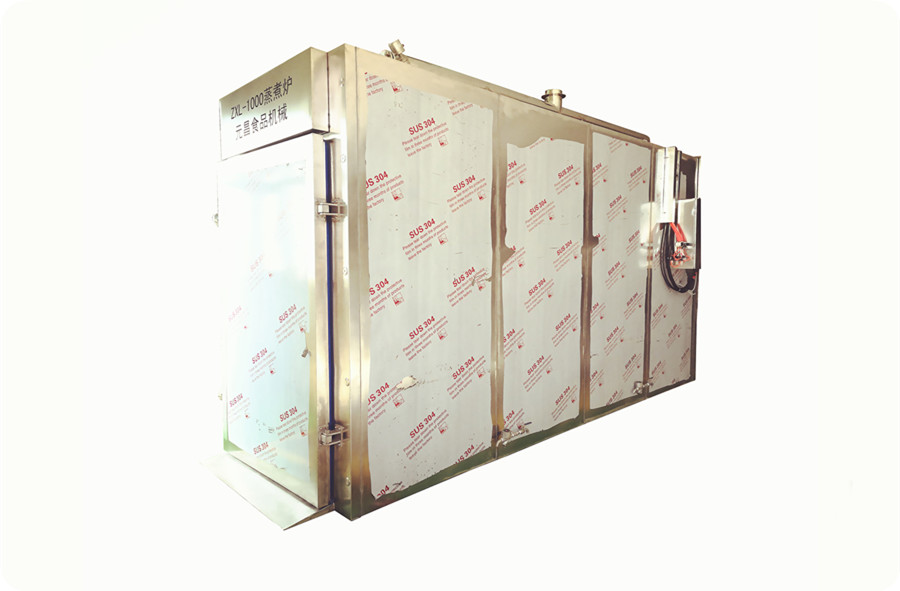

3.5. Cooking

Cook for 1-2h at 75-80℃, when the core temperature reaches 68℃.

3.6. Smoking

Smoked at 50°C for 30-60min, the outer surface of the ham is brown and has a smoky flavor.

3.7. Cooling

The cooling process works better in water. The water temperature is required to be 10-12°C. After cooling for 4 hours, the center temperature of the product is 27°C, and then sent to a refrigerated room at 2-4°C for 12 hours. When the product temperature drops to 1-2°C, the finished product is obtained. Finally, it is packaged with biaxially stretched film.

4. Product Quality

The color and appearance of the product are tan. It has the delicious, crispy smell that ham should have, and the special flavor of smoky. The meat is tight, tender, and elastic, with obvious meat chunks and no impurities. The casing is dry and complete, and is tightly combined with the contents. Full of elasticity, tight flesh, no mucus, and mildew. The cut surface is firm and moist, and the flesh is evenly rose red. The fat is white and has the unique aroma of Western-style ham.

5. Precautions

- 5.1. It is necessary to destroy the tissue structure of the meat as little as possible, and strive to maintain the original structure of the meat, so that the injected brine can be more retained in the muscles.

- 5.2. The equipment used in ham production, such as brine injector machine, tumblers, curing containers, molds, etc., are often used alternately. If it is not cleaned and disinfected in time after each use, a large number of microorganisms will accumulate and become one of the main sources of pollution in the production of ham.

- 5.3. Strictly control the pickling and smoking process conditions to ensure the quality of the products.