1. Hygienic Requirements for Casing Raw Materials

Carcasses from healthy animals must be collected and processed immediately after opening to prevent autolysis or spoilage of the gut. The collected intestinal raw materials should be carefully inspected, and a complete set of intestinal tubes with malignant infectious diseases such as anthrax, rinderpest, enterotoxemia, or toxic diseases such as hydrochloric acid, organic phosphorus, and organic chlorine should be chemically processed or destroyed. . Intestinal tubes found to have combined lesions, swine fever lesions, and various enteritis changes should not be processed into casings. Appropriate harmless treatment can be carried out according to the nature and severity of the lesions.

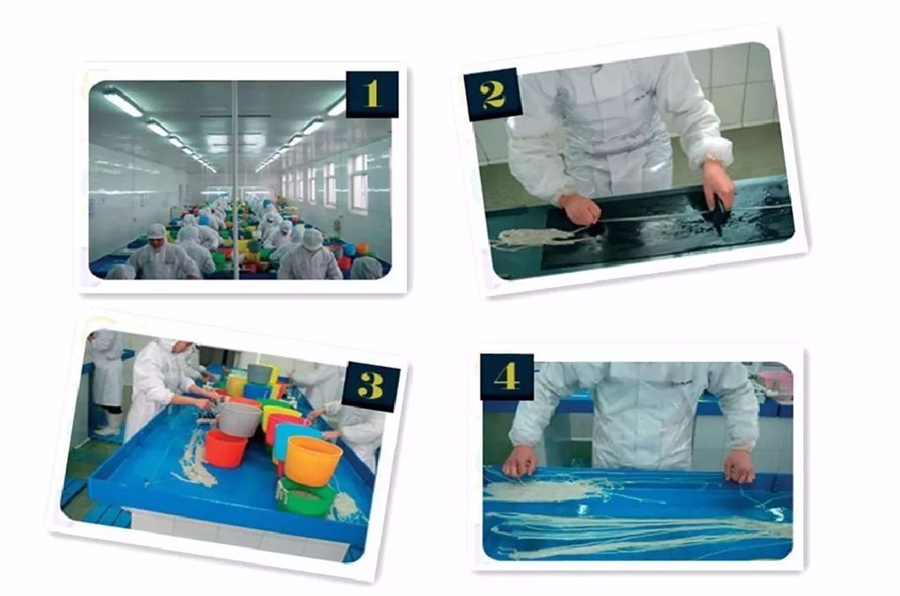

2. Hygienic Requirements for Casing Processing

Preliminary processing of casings begins with the collection of raw materials. Including removal of intestinal contents, removal of the mesentery, separation of intestinal fat, scraping of the intestinal mucosa, rinsing with water, shunt binding, salting, or drying. In the process of casing processing, a large amount of waste generated should be removed in time and chemically processed. The workshop floor, equipment, staff utensils, etc., shall be cleaned and disinfected according to the hygiene requirements of the slaughtering workshop.

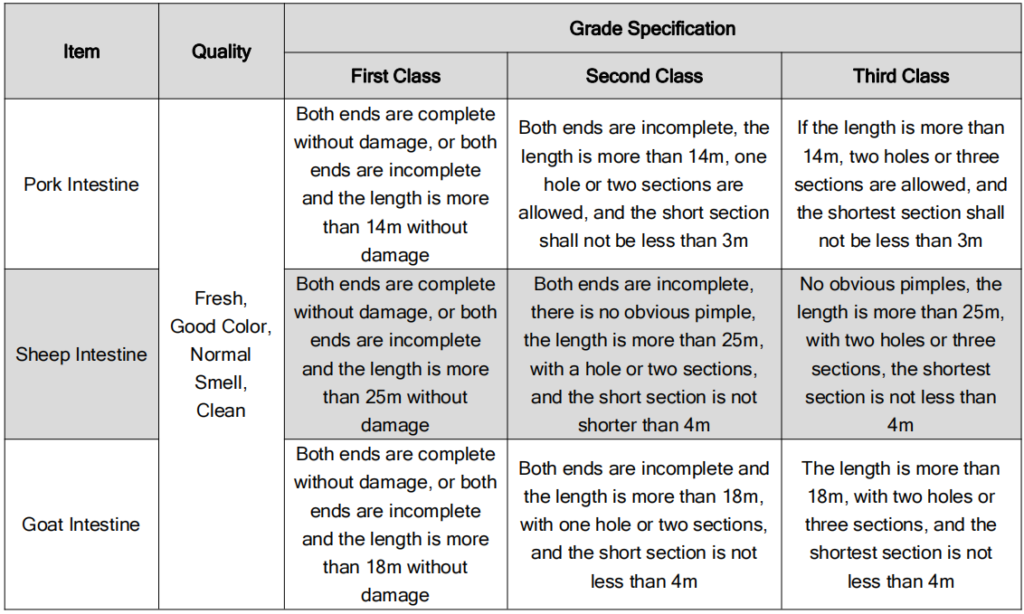

Sensory Quality Requirements of Raw Casings for Pigs, Sheep, and Goats

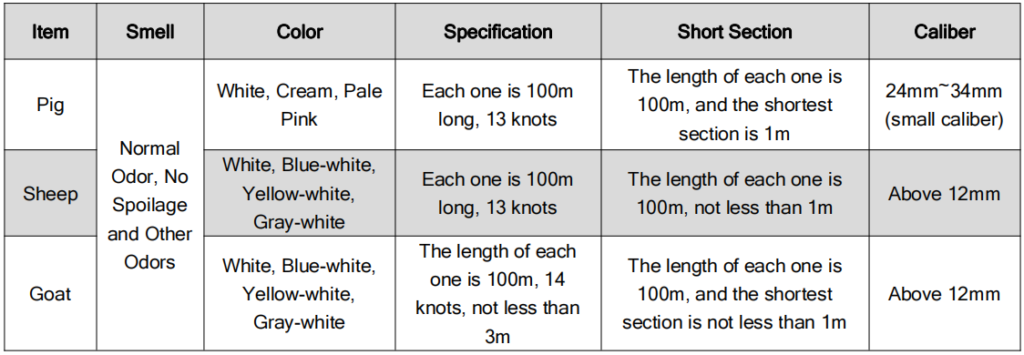

Sensory Quality Requirements of Semi-finished Products for Pig, Sheep, and Goat Casings

3. Common Defects and Sanitary Treatment of Casings

3.1. Pollution

3.1.1. Reasons and Characteristics:

Fecal residue adheres to the intestinal wall due to contamination by the contents during processing.

3.1.2. Sanitary Treatment

Lightly soiled casings can be eaten after careful washing to remove dirt. If it is seriously polluted, it is impossible to remove the intestinal tube of the fecal residue for industrial use or chemical production.

3.2. Putrefaction

3.2.1. Reasons and Characteristics

Raw materials that are not fresh, salted insufficiently or spoiled when stored at high temperatures. Corruption results in bowel blackened, smelly, sticky, and easy to tear.

3.2.2. Sanitary Treatment

Mild corruption can be dried in a cool and ventilated place to drive off odor, or rinsed with 0.01%–0.2% potassium permanganate solution to inhibit corruption and decomposition. Slightly spoiled casings can be eaten after processing, but should not be stored. If it is obviously corrupt, it will be transformed or destroyed.

3.3. Brown Spots

3.3.1. Reasons and Characteristics

The salt used in salting is not pure, mixed with iron salt (above 0.005%) and calcium salt (trace). They can form water-insoluble protein compounds with intestinal proteins. Rough brown spots appear on the bowel wall, and the bowel narrows.

3.3.2. Sanitary Treatment

The casings with mild brown spots are first treated with 2% dilute hydrochloric acid, then washed with a soda solution, and can be eaten after removing the brown spots. Severely browned casings are not edible.

3.4. Erythema

3.4.1. Reasons and Characteristics

It is caused by Chromoococcus halophila and some Chromobacterium. When salted casings are stored at 12-35°C, after 10 days, rose-red plaques appear on the non-water-soaked intestines, giving the casings a garlic odor.

3.4.2. Sanitary Treatment

Mild erythema is consumed without restriction. In severe cases, it should not be used as food and should be processed.

3.5.Green Marks

3.5.1. Reasons and Characteristics

It is caused by the chemical reaction between the tannic acid in the wooden barrel and the iron salt on the casing, which makes the casing near the barrel wall appear blue-black spots.

3.5.2. Sanitary Treatment

Mild blue marks are not restricted for consumption. In severe cases, it should not be used as food and should be processed.

3.6. Mildew

3.6.1. Reasons and Characteristics

Due to the high storage temperature and relative humidity, dry casings will lead to the growth and development of various molds and mildew spots.

3.6.2. Sanitary Treatment

The mildew layer is slightly removed and edible. In serious cases, use it for industrial use or destroy it.

3.7. Enteric Fatty Acid

3.7.1. Reasons and Characteristics

Salt-cured pig large intestine contains 15%-20% fat in the intestinal wall, and salt-cured beef casings tend to contain 3%-5% fat. When the casing is stored in poor conditions, the fat can quickly rancid under the action of air, light, high temperature, and microorganisms, resulting in an unpleasant odor.

3.7.2. Sanitary Treatment

The casings that have been spoiled by enteric fatty acids should not be eaten and should be processed or destroyed.