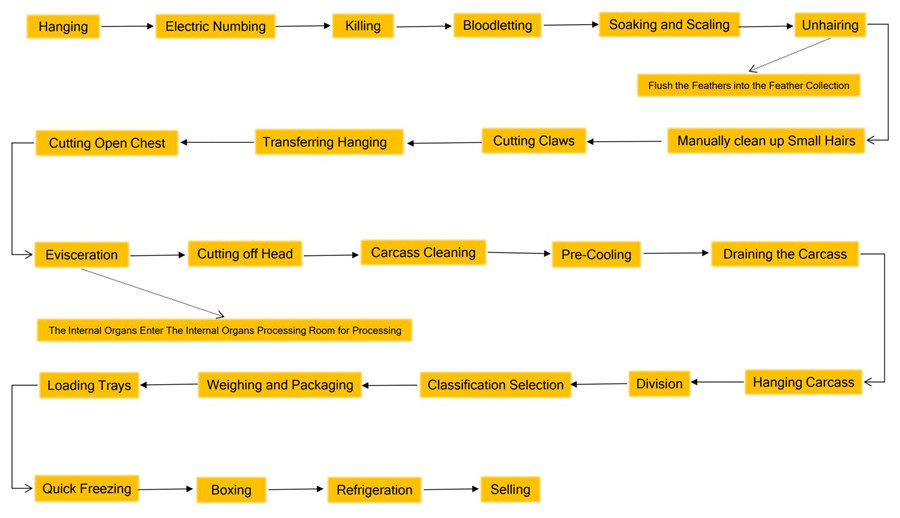

Schematic Diagram of Broiler Slaughter

Broiler Slaughter Process:

Step 1: Chicken Receiving

1.1. Once trucks arrive at the processing plant, please observe all chickens before unloading. If no abnormality is found, then ask for the certificate of conformity, which is issued by the animal epidemic prevention supervision agency of the place of origin. Only when the certificate matches the goods, the trucks are allowed to be unloaded.

1.2. During unloading, the quarantine personnel will do an on-site inspection. The cages of healthy chickens will be placed on the conveyor and transported to the hanging room.

1.3. The hanging room is strictly separated from the slaughter workshop, and needs to be designed as dark as possible. Because once chickens are exposed to strong light, they will flap wings and cause excessive tension.

1.4. The chicken-hanging staff took out the chicken from cages, hold the chicken belly and hang two feet on the racks of the production line. Each person could hang 800-1000 chickens per hour.

1.5. The empty chicken cages will be automatically transported by the conveyor into the chicken cage cleaning machine. After cleaning, they will be uploaded to the platform through the slide. In order to be used again.

Step 2: Broiler Slaughtered and Depilated

2.1. The main processes completed by the chicken slaughter overhead conveyor line are: hanging, electric numbing, killing, bloodletting, soaking and scalding, unhairing, cutting claw, transferring hanging, etc.

2.2. The racks spacing of overhead conveyor line: 6 inches(152.4mm). It adopts a standard drive chain(chain pitch t=25.4mm), frequency conversion speed regulation.

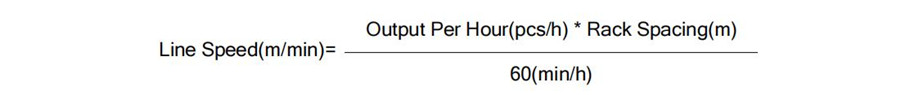

The design slaughter capacity is closely related to the line speed of the production line. The calculation formula of the line speed is as below.

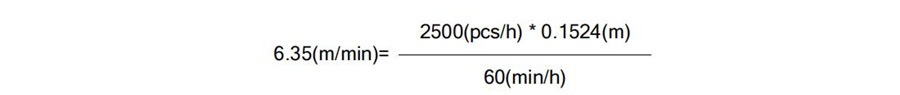

For example, design slaughter capacity is 2500 pcs/hour, then the line speed should be 6.35m/min

2.3. The chicken electric numbing usually adopts water bath type, electric voltage: 70-90v, time: 2-3s. Or do not pass the electric numbing process, only use the overhead conveyor line automatically transport. After 1 minute, the chicken will be calm down, then ready to be killed.

2.4. After killing, drain the blood, draining time: 3-4 minutes. And then soaking and scalding, which adopts constant temperature of 58-62℃, time: 40-60s. It’s better to use hanging unhairing way, to avoid the carcass cross-infection, time: 15-30s.

Steps 3: Cut Open the Chest and Evisceration

3.1. The main processes completed by the chicken evisceration overhead conveying line are: cutting open the chest, evisceration, cutting off head cutting, carcass cleaning, etc

3.2. The racks spacing of overhead conveyor line: 8 inches(203.2mm). It adopts a standard drive chain(chain pitch t=25.4mm), frequency conversion speed regulation.

3.3. Put the removed viscera into the visceral chute and inspect it by the quarantine personnel. The qualified ones enter the visceral processing room for processing. And the qualified chicken carcass enters the next process. The unqualified ones are put in a closed trolley, which will be taken out of the slaughterhouse for processing.

3.4.Visceral Processing: Cleaning the intestines. Using a gizzard degreasing machine to remove the grease on the surface, and then peel off the gizzards with the peeling machine. All cleaned ones will be put into the cold storage.

3.5. Carcass Processing: The carcass after gutting must be cleaned before pre-cooling to remove blood from the body.

Step 4. Pre-cooling

4.1. There are two ways for pre-cooling, one is pool pre-cooling, and the other one is using a spiral pre-cooling machine. The area occupied by pool pre-cooling is larger than the spiral pre-cooling machine.

4.2. The pre-cooled carcass should be drained by a drain machine or overhead conveyor line.

4.3.The core temperature of the pre-cooled chicken carcass should be below 10℃.

Step 5. Division and Packaging

5.1. Temperature control in the division and packaging room: 10-12℃

5.2. The rack spacing of division overhead conveying line: 8 inches(203.2mm). It adopts standard drive chain(chain pitch t=25.4mm), frequency conversion speed regulation.

5.3. On the overhead conveyor line, there are segmentation operators to segment the meat of different parts. And then put them on the flat conveyor to transfer to the sorting station for sorting.

5.4. After sorting, they will be weighed and vacuum packaged. Use the trolleys to push them into the cold storage (-30℃). Or the finished product cooling room (0-4℃) to keep it fresh.

5.5. Boxing the frozen ones, then put into the freezer (-18℃) for storage.

5.6. Delivery and Selling