1. Basic Requirements

1.1. Slaughter Qualification:

Possess a legal and effective pig slaughter certificate, industrial and commercial business license, animal epidemic prevention qualification certificate, and pollution discharge permit.

1.2. Slaughter Scale:

The designed annual slaughter capacity is more than 300,000 heads, and the cutting capacity is more than 60,000 heads.

2. Site Selection and Plant Environment

2.1. Site Selection:

2.1.1. More than 500 meters away from drinking water sources, animal breeding farms, breeding areas, and animal bazaars; more than 3,000 meters away from breeding stocks and poultry farms; more than 200 meters away from animal diagnosis and treatment sites; more than 3,000 meters away from animal isolation sites and harmless treatment sites more than meters.

2.1.2. There should be no areas with significant contamination to food in the plant area. It should be far away from polluted water bodies and should avoid industrial enterprises that produce harmful gases, smoke, dust, and other pollution sources or other areas or places that produce pollution sources.

2.1.3. The plant site must have water and power sources that meet the requirements of the slaughter enterprise setup plan.

2.2. Plant Environment:

2.2.1. The clean area and non-clean area in the factory should be strictly separated, and a fence should be built around it.

The non-clean areas include: raw material receiving area, slaughter waiting room, emergency slaughter room, harmless treatment room (temporary storage room), waste collection place, sewage treatment station, boiler room.

2.2.2. The production area must have separate entrances and exits for pigs and waste, and separate entrances and exits for products and personnel. It’s prohibited to use the same channel for products, live pigs, and waste.

2.2.3. The main roads in the plant area should be hardened (such as concrete or asphalt pavement, etc.), and the pavement should be smooth, easy to wash, and have no water accumulation.

2.2.4. The plant area should be equipped with waste and garbage temporary storage or treatment facilities. Waste should be cleared or treated in time to avoid pollution to the plant environment. Waste equipment and other sundries should not be piled up in the plant area.

3. Laboratory Construction Requirements

Need to build an inspection room. Testing equipment is PCR testing system, microscope, constant temperature incubator, oven, water bath, dryer, one ten-thousandth balance, thermometer and hygrometer, 4℃ refrigerator, low-temperature refrigerator, sampler, microplate reader, ultra-clean work Table, high-temperature sterilizer, Kjeldahl nitrogen distillation glass device, burette, etc.

4. Personnel Requirements

4.1. Health Requirements:

Personnel engaged in slaughter, inspection (testing), and management shall hold health certificates issued by medical institutions at or above the county level.

4.2. Inspectors:

Equipped with meat inspectors who are suitable for the scale of the slaughter, and already passed training and assessment.

4.3. Laboratory Inspection Personnel Qualification:

They should have a college degree or above or equivalent education level in related majors such as veterinary medicine, food, or chemistry.

5. Management Requirements

5.1. Quality Management System:

The slaughter plant is established with pig slaughter quarantine declaration, pig entry inspection registration, broker filing management, waiting for slaughter, meat quality inspection, detection of risk substances such as clenbuterol, animal epidemic report, pig product traceability, cleaning and disinfection, and hygiene management, Non-hazardous treatment, food processing aids, and chemical use management, emergency management and other pig slaughter quality management systems.

5.2. Production Management System:

The slaughter plant has established a pig slaughter production management system such as training, safety production, information submission, use of badges and signs, daily use of facilities and equipment, inspection and maintenance of facilities and equipment, management of slaughter employees, and recall of defective products.

6. Slaughter Requirements

6.1. Quality Management System:

6.1.1.Live pig entrance inspection and registration: Check the entry of live pigs and the records of the local livestock and poultry slaughter management system to see if entry inspections and registrations are carried out.

6.1.2. Cleaning and Disinfection: Clean and disinfect the pig carts after unloading pigs as required and then leave the field and record them completely.

6.1.3. Self-inspection of African Swine Fever: Use PCR detection method according to regulations, slaughter pigs in batches every day, sample each head, test each batch, and issue a test report.

6.1.4. Waiting to be Slaughtered: By checking the animal quarantine certificate for slaughter and the records of the local livestock and poultry slaughter management system, you can see whether the slaughter permit is issued for more than 12 hours(a different country the time will be different).

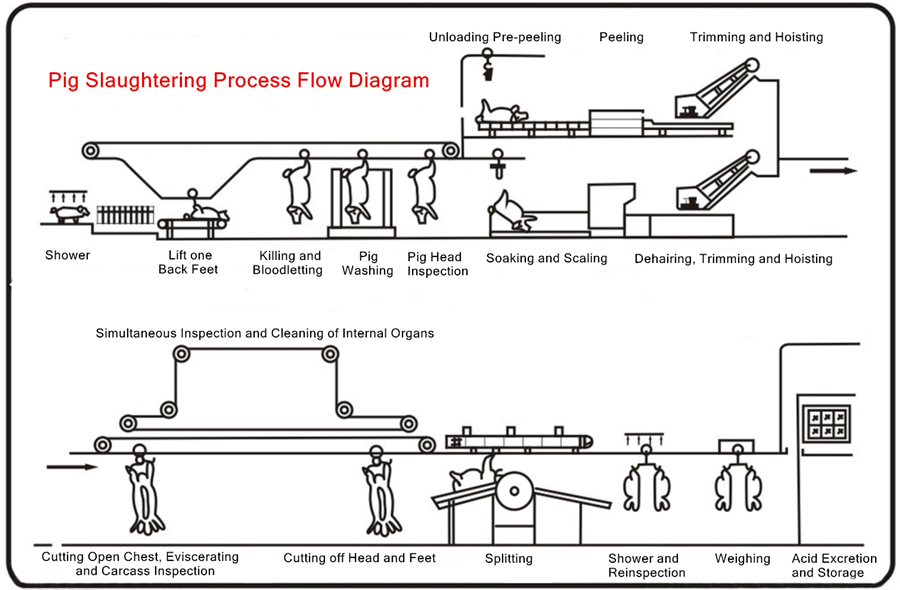

6.2. Slaughter Operation:

6.2.1The slaughter of pigs should be showered, stunned, killing and bleeding, pre-washed, scalded and depilated or peeled, singed, washed, heads and hooves and tails removed (or after opening), intestines sealed, cleansed, split in half, trimmed, tidied Basic technological process such as by-products.

Failure to slaughter in accordance with the basic process, or pre-cleaning before scalding, or removing the head and hoof, opening or half-cutting before singeing hair, are all non-conformances.

6.2.2.From stunning to killing and bleeding, the time should not exceed 30 seconds; the bleeding time should not be less than 5 minutes

Bleeding without being stunned is not in compliance.

6.2.3. The carcass and by-products do not touch the ground or fall to the ground.

7. Safe Production

The boilers, high-pressure vessels, and liquid ammonia storage equipment of slaughter enterprises shall obtain the license for the use of special equipment and hazardous chemical storage equipment. Personnel engaged in special equipment operations should be trained and qualified to obtain corresponding qualifications.

There should be 1. Special emergency plans for special equipment accidents; 2. Special equipment inspection reports (regular inspection reports for pressure vessels); 3. Qualification certificates for special equipment operators (electricians, refrigeration workers, boiler workers, forklift workers).

PS: The above information is only for learning reference. The detailed construction requirements for pig slaughter need to be consistent with your local regulations.