As we know chicken meat is delicious and healthy for our body, because the protein content is high, and easily absorbed and utilized by the human body. But not all of us know that the gizzard is good for us too.

Gizzard contains protein, fat, cholesterol, carbohydrates, vitamin A, vitamin B1, vitamin B2, vitamin E, calcium, phosphorus, iron, potassium, sodium, magnesium, zinc, selenium, and stomach Hormone, keratin, trace pepsin, amylase, and other nutrients. All are necessary by our bodies. And it’s very delicious.

Here is an industrial cooking method. Hope it could give a spark to your business.

1. Recipe Ingredients

1.1. Marinating Ingredients: Raw materials (calculated in 100kg)

| Item | Volume |

| Salt | 3kg |

| Soy Sauce | 0.4kg |

| Vinegar | 3.2kg |

| High White Wine | 0.5kg |

| Cold Boiled Water | 30kg |

1.2. Marinated Ingredients: Raw materials (calculated in 100kg)

| Item | Volume |

| Salt | 1.5kg |

| Monosodium Glutamate | 0.3kg |

| White Sugar | 0.5kg |

| Soy Sauce | 0.8kg |

| Green Onion | 0.8kg |

| Ginger | 0.4kg |

| Pepper | 0.1kg |

| White Wine | 0.2kg |

| Chili Powder | 0.05kg |

| Water | 40kg |

1.3. Cooking Ingredients (calculated in 100kg)

| Item | Volume |

| Salt | 0.5kg |

| White Sugar | 0.3kg |

| Monosodium Glutamate | 0.2kg |

| Chopped Green Onion | 0.8kg |

| Ginger | 0.4kg |

| White Wine | 0.2kg |

| Soy Sauce | 0.5kg |

| Vegetable Oil | 1.8kg |

| Chili Powder | 0.1kg |

| Compound Spice Juice | 0.2kg |

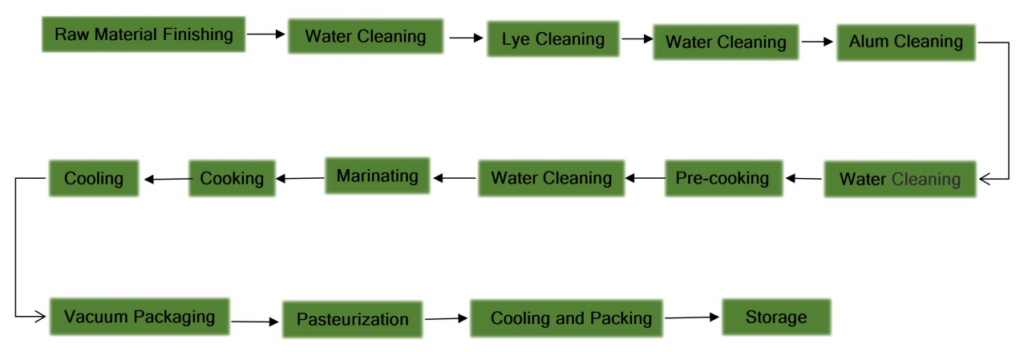

2. Processing Flow

3. Key Points of Operation

3.1.Raw Material Finishing

The gizzard is required to be cut one by one with scissors and washed away the residual feed and impurities.

3.2. Alkaline Cleaning

Dissolve 1.5kg edible alkali in 20kg warm water (30 ℃ ~ 40 ℃) and pour it into 100kg washed raw material. Stir it quickly with a mixer for 40 ~ 60min until the glandular liquid on the inner wall of the raw material is completely dissolved, and then rinse it with clean water until the water is no longer yellow.

3.3. Alum Cleaning

Dissolve 0.5kg alum in 10kg warm water (40 ℃ ~ 60 ℃), pour it into the alkali-washed raw material, quickly stir it with a mixer for about 40min, and then wash it with clean water until the cleaning water is no longer yellow.

3.4. Ingredient Curing

Prepare various auxiliary materials according to the curing formula and mix them fully in cold boiled water. Then pour the treated raw materials into the curing solution and stir them evenly. Marinate them at 0 ~ 4 ℃ for 18 ~ 20h. During this period, pay attention to turning the cylinder twice.

3.5. Pre-cooking

Rinse the pickled raw materials with clean water and fish them. Then boil in boiling water for 5 ~ 8min and stir while cooking until the raw material solidifies and shrinks to white. Remove and pre-cool in cold water.

3.6. Marinating

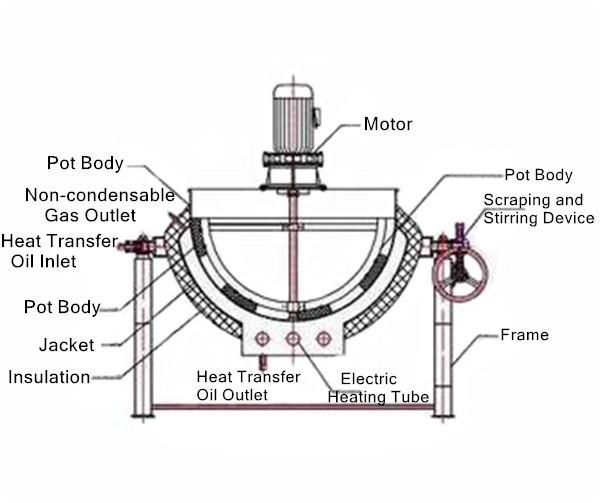

Prepare various auxiliary materials according to the marinated formula. First, heat the water in a jacketed pot to boiling, then add various auxiliary materials one by one, and stir evenly. Then add the pre-cooked ingredients to the soup and keep it boiling for 1 to 1.5 hours.

3.7. Cooking

Prepare various auxiliary materials according to the Cooking formula. First, remove the marinated semi-finished product from the soup, then pour the vegetable oil into a clean pot, heat it to 170~180℃, then add the onion, ginger, chili powder, etc. Burn the aroma, then add the semi-finished product to the stir fry, add other auxiliary materials while stir fry, wait until it is evenly stirred, and then continue to stir for 30 to 50 minutes to get out of the pot.

Various auxiliary materials are prepared according to the Cooking formula. First, take the marinated semi-finished product out of the soup, then pour the vegetable oil into a clean pot and heat it to 170-180°C. Then add green onion, ginger, chili powder, etc., and fry until it is burnt. Then add the semi-finished product to stir fry, and add other auxiliary materials while Cooking. After stirring evenly, continue to stir-fry for 30 to 50 minutes to get out of the pot.

3.8. Cooling, Packaging and Sealing

Place the product in a ventilated place to dry for 1 to 2 hours to be divided into packaging. When filling the bag, be careful not to get oil on the mouth of the bag. The weight of each bag is determined according to their own requirements, and then vacuum seals.

3.9. Sterilization and Cooling

Boil the packaged product in hot water at 88°C for 40 minutes, and then place it in a 0-4°C environment to cool after pre-cooling.

3.10. Packing and Warehousing

After the product is cooled to the core temperature below 8℃, it can be packed. Pack the label and print the production date. And store it in a dry warehouse at 0~4℃.